Exploring the Benefits of Advanced Conical Rubber Core Annular Blowout Prevention Technology in High Altitude Machinery

In the manufacturing and processing machinery industry, safety is paramount, especially when it comes to high altitude operations. Advanced conical rubber core annular blowout prevention technology has emerged as a game-changer in ensuring the safety and efficiency of high altitude machinery.

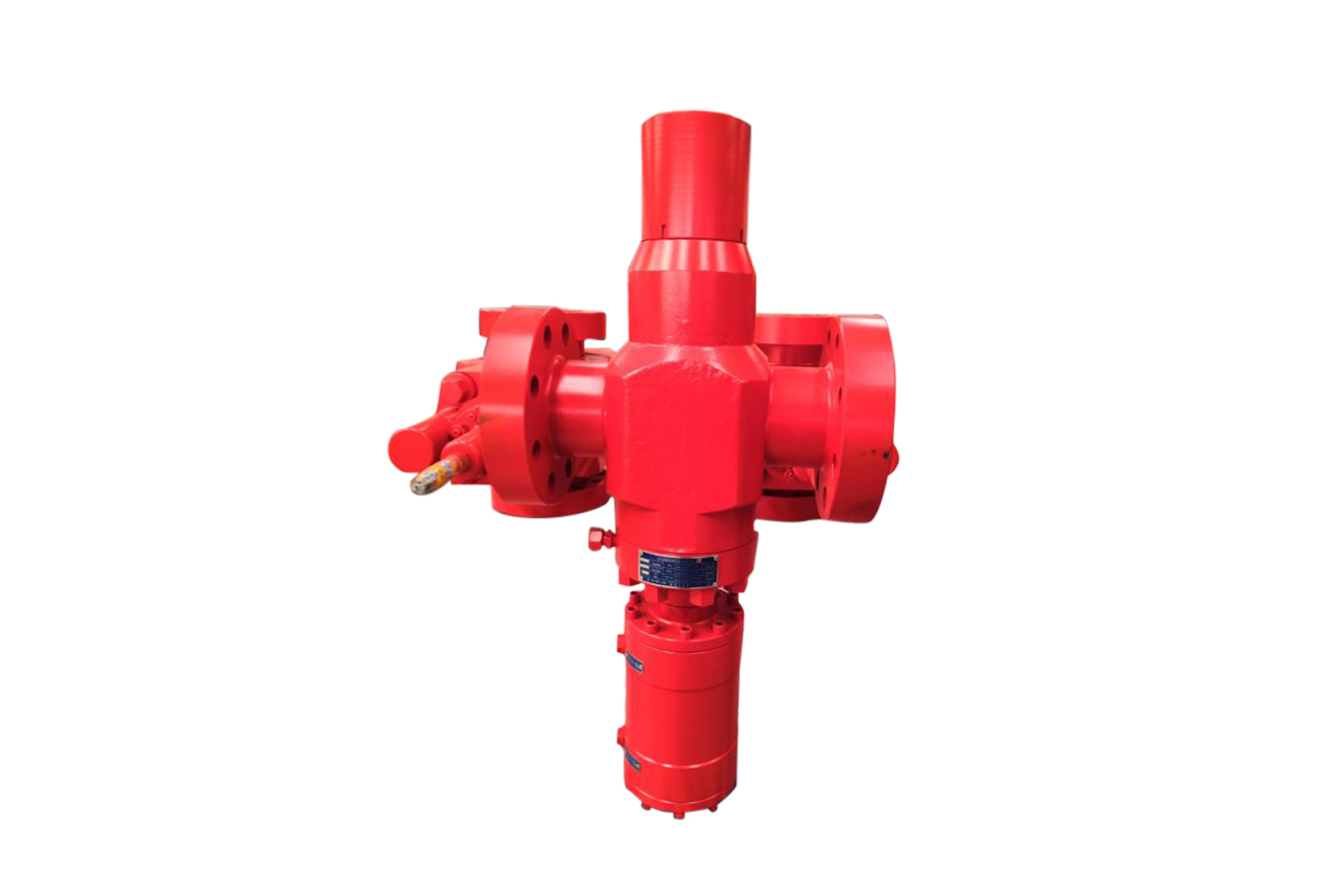

This innovative technology works by utilizing a conical rubber core to prevent blowouts in the annular space. By creating a secure seal, it reduces the risk of sudden tire failures, which can be catastrophic in high altitude environments. This not only enhances the safety of operators but also prolongs the lifespan of the machinery.One of the key benefits of this technology is its ability to improve stability and traction in high altitude machinery. The conical rubber core provides enhanced grip on various surfaces, reducing the risk of slippage and accidents. This is particularly crucial in engineering and construction machinery, where stability is essential for precision and safety.

Additionally, advanced conical rubber core annular blowout prevention technology helps to minimize downtime and maintenance costs. By preventing blowouts and tire failures, machinery operators can focus on their work without interruptions. This leads to increased productivity and cost savings in the long run.

Overall, the implementation of advanced conical rubber core annular blowout prevention technology in high altitude machinery is a significant step towards enhancing safety, efficiency, and reliability in the manufacturing and processing industry. As technology continues to advance, it is crucial for businesses to stay updated with the latest innovations to stay competitive in the market.

评论

发表评论