Innovative Technology for Preventing Blowouts in Coiled Tubing Operations

In the world of manufacturing and processing machinery, the industry of engineering and construction machinery stands out for its continuous innovation and technological advancements. One area that has seen significant progress in recent years is the development of innovative technology for preventing blowouts in coiled tubing operations.

## What are Coiled Tubing Operations?Coiled tubing operations involve the use of a continuous, flexible steel pipe (known as coiled tubing) that is spooled on a large reel and then uncoiled and pushed into wellbores for a variety of applications. These operations are crucial in the oil and gas industry for tasks such as well intervention, cleanouts, and hydraulic fracturing.

## The Importance of Preventing Blowouts

Blowouts in coiled tubing operations can have devastating consequences, leading to safety hazards, environmental damage, and costly downtime. It is imperative for companies in the manufacturing and processing machinery industry to prioritize safety and invest in cutting-edge technology to prevent blowouts.

## Innovative Technology Solutions

### Real-Time Monitoring Systems

One of the key advancements in preventing blowouts is the development of real-time monitoring systems that continuously track pressure, temperature, and other critical parameters during coiled tubing operations. These systems provide operators with instant feedback and alerts, allowing them to take immediate action in case of abnormalities.

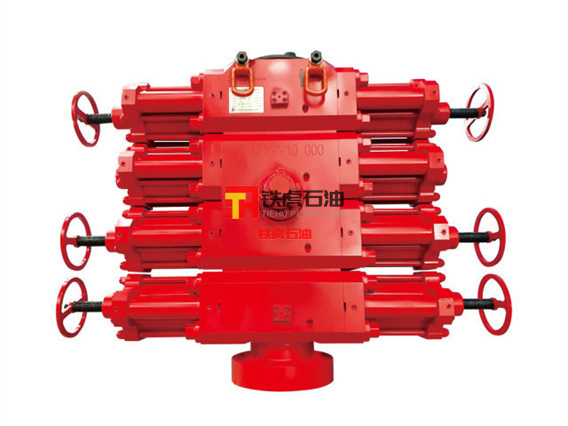

### Blowout Preventers

Blowout preventers (BOPs) are essential safety devices that are designed to seal off the wellbore in case of a blowout. Recent innovations in BOP technology have led to the development of more efficient and reliable systems that can quickly respond to high-pressure situations and prevent catastrophic events.

## FAQs

### Q: How common are blowouts in coiled tubing operations?

A: While blowouts are rare, they can have severe consequences, making it crucial for companies to invest in advanced technology for prevention.

### Q: What are the benefits of real-time monitoring systems?

A: Real-time monitoring systems provide operators with immediate feedback and alerts, allowing them to take proactive measures to prevent blowouts.

### Q: How do blowout preventers work?

A: Blowout preventers are safety devices that seal off the wellbore in case of a blowout, preventing the uncontrolled release of fluids.

## Conclusion

In conclusion, innovative technology plays a crucial role in preventing blowouts in coiled tubing operations. By investing in cutting-edge solutions such as real-time monitoring systems and blowout preventers, companies in the manufacturing and processing machinery industry can ensure the safety of their operations and minimize the risk of catastrophic events. It is essential for industry professionals to stay informed about the latest advancements in technology and prioritize safety in all aspects of their work.

评论

发表评论