Understanding Molybdenum Filament: Properties, Applications, and Benefits

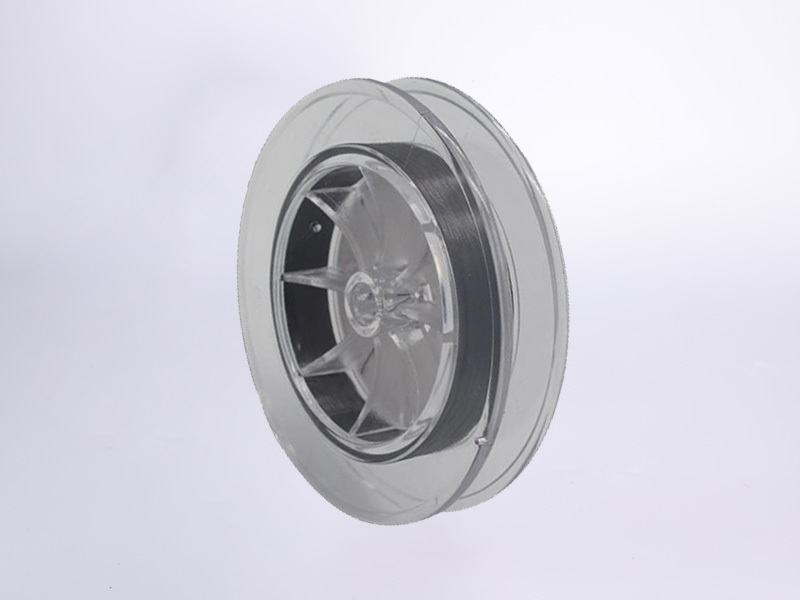

discount Molybdenum filament is a product derived from molybdenum, a versatile and high-performance metal known for its excellent thermal and electrical conductivity, high melting point, and exceptional strength at elevated temperatures. These properties make molybdenum filament an ideal candidate for various industrial applications, particularly in environments that demand resilience and reliability.

One of the most significant advantages of classy Molybdenum filament is its ability to withstand extremely high temperatures. With a melting point of approximately 2,623 degrees Celsius (4,753 degrees Fahrenheit), molybdenum remains stable and maintains its structural integrity even under severe thermal stress. This quality is particularly beneficial in industries such as aerospace, electronics, and lighting, where components are often subjected to harsh conditions.

In the realm of electronics, Molybdenum filament Chinese is commonly utilized in the production of cathodes and other essential components in vacuum tubes and semiconductors. Its excellent conductivity allows for efficient electron emission, which is vital for the performance of various electronic devices. Moreover, molybdenum filament is also employed in the construction of filaments for high-intensity discharge lamps, providing a reliable source of light with minimal energy loss.

Another notable application of molybdenum filament can be found in the field of thermal processing. Molybdenum is often used as a crucible material in the production of high-purity materials, as it does not react with most molten metals and can withstand the high temperatures required during processing. This ensures that the final products maintain their purity and quality, which is essential in many advanced manufacturing processes.

In addition to its thermal and electrical properties, molybdenum filament also exhibits excellent corrosion resistance, making it suitable for applications in harsh chemical environments. This durability extends the lifespan of components made from molybdenum filament, ultimately leading to reduced maintenance costs and improved operational efficiency.

Furthermore, the use of molybdenum filament contributes to various sustainability efforts. As industries increasingly seek to reduce their environmental impact, molybdenum's durability and efficiency can help decrease energy consumption and waste generation in manufacturing processes.

In summary, molybdenum filament is an indispensable material in many high-temperature and high-performance applications. Its unique properties, including high melting point, excellent conductivity, and corrosion resistance, make it a preferred choice in the metallurgy and metal materials industry. As industries evolve and seek innovative solutions for energy efficiency and sustainability, the demand for molybdenum filament is likely to continue growing, underscoring its importance in modern manufacturing and technology.

评论

发表评论