Understanding the Importance and Functionality of Famous Oil Breather Filters

china Oil breather filters supply are essential components in many industrial applications, particularly in machinery and equipment that utilize lubrication systems. These filters are designed to allow the necessary ventilation of oil-filled compartments while preventing contaminants from entering the system. Understanding their functionality and importance can help enhance the performance and reliability of industrial equipment.

The primary function of an classy oil breather filter is to regulate air exchange in oil-filled enclosures, such as gearboxes, crankcases, and hydraulic systems. As machinery operates, temperature changes and oil movement create a vacuum, necessitating the introduction of air. Without an effective breather filter, unfiltered air can carry moisture, dust, and other pollutants into the oil, leading to degradation and potential failure of the lubrication system.

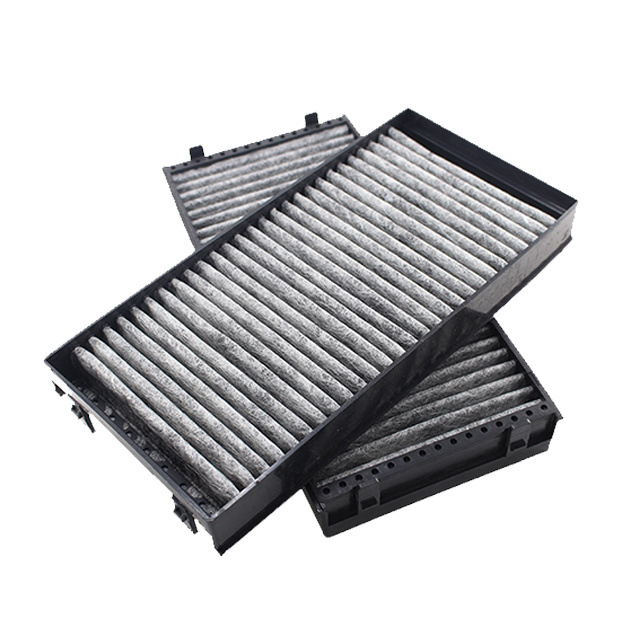

One key aspect of famous oil breather filters manufacturers is their construction, which typically includes a filter medium and a housing designed to withstand harsh operating conditions. The filter medium is often made from materials that can trap both particulate matter and moisture while allowing air to flow freely. This design helps maintain optimal pressure levels within the system, preventing issues such as cavitation or oil starvation.

In addition to preventing contaminants from entering the oil, oil breather filters also play a critical role in maintaining the quality of the lubricant itself. By keeping the oil clean and free from harmful particulates, these filters help extend the life of the oil and reduce the frequency of oil changes. This can result in significant cost savings for businesses involved in industrial operations.

Moreover, the installation of high-quality oil breather filters can enhance the overall efficiency of machinery, contributing to improved performance and reduced downtime. When equipment operates smoothly and efficiently, it not only increases productivity but also minimizes the likelihood of unexpected repairs and maintenance needs.

Another important consideration is the maintenance of oil breather filters. Regular inspection and replacement are vital to ensure their efficacy. Over time, filters can become clogged with dirt and debris, which can impede airflow and result in pressure imbalances. A proactive maintenance schedule can help identify when a filter needs to be cleaned or replaced, ensuring optimal performance of the machinery.

In conclusion, famous oil breather filters supplier are indispensable in industrial settings, providing crucial protection for lubrication systems. By understanding their functionality and the advantages they offer, businesses can make informed decisions regarding their equipment maintenance and operational efficiency. Investing in quality oil breather filters is not just about compliance; it's about safeguarding the longevity and reliability of industrial machinery, ensuring a smoother operation overall.

评论

发表评论