The Pinnacle of Manufacturing Excellence: High Precision CNC Machining Parts

In modern manufacturing, High Precision CNC Machining Parts represent the convergence of cutting-edge technology, engineering mastery, and relentless pursuit of perfection. As industries demand tighter tolerances, complex geometries, and flawless surface finishes, Computer Numerical Control (CNC) machining has emerged as the gold standard for producing components that meet and exceed these expectations.

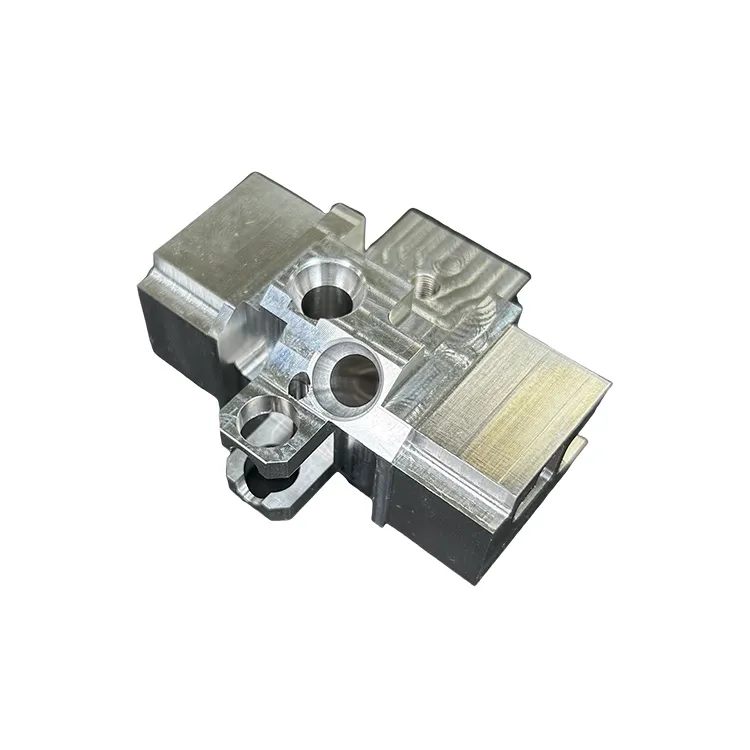

High Precision CNC Machining Parts are engineered to achieve tolerances as tight as 0.005 mm or finer, ensuring seamless functionality in environments where even microscopic deviations can lead to failure. Unlike conventional machining methods, which rely heavily on manual labor and iterative adjustments, CNC machining leverages computer-aided design (CAD) software and automated tooling to execute commands with unparalleled accuracy. This process begins with a digital 3D model, which is translated into machine-readable code (G-code), guiding multi-axis mills, lathes, and grinders to shape raw materials into finished parts. The result is a production method that eliminates human error, accelerates cycle times, and enables mass customization.

The automotive sector also benefits from High Precision CNC Machining Parts, particularly in electric vehicle (EV) manufacturing. Battery casings, motor housings, and lightweight chassis components require intricate designs to balance performance and energy efficiency. CNC machining enables the integration of cooling channels, threaded inserts, and assembly interfaces into single parts, reducing weight and assembly complexity. Beyond these sectors, industries like robotics, optics, and defense leverage CNC-machined components for their durability and exacting specifications.

Advancements in Material Science and tooling technology further amplify the capabilities of high precision CNC machining. Modern machines can process superalloys like Inconel, titanium, and hardened steels, which were once deemed too challenging to machine. Combined with coatings such as titanium nitride (TiN) and diamond-like carbon (DLC), cutting tools now endure higher speeds and temperatures, extending lifespans and improving surface finishes. Additionally, the integration of artificial intelligence (AI) and machine learning (ML) optimizes machining parameters in real time, predicting tool wear and adjusting feeds/speeds to maintain precision.

The future of High Precision CNC Machining Parts lies in hybridization with additive manufacturing (3D printing). While 3D printing excels in producing complex geometries, CNC machining ensures dimensional accuracy and surface quality. This synergy allows manufacturers to combine the best of both worlds: printing near-net-shape components and finishing them with CNC tools to achieve final specifications. Furthermore, the rise of Industry 4.0 and smart factories will see CNC machines connected via IoT networks, enabling predictive maintenance, remote monitoring, and adaptive production workflows.

评论

发表评论