Unveiling the Significance and Versatility of Cnc Mechanical Parts

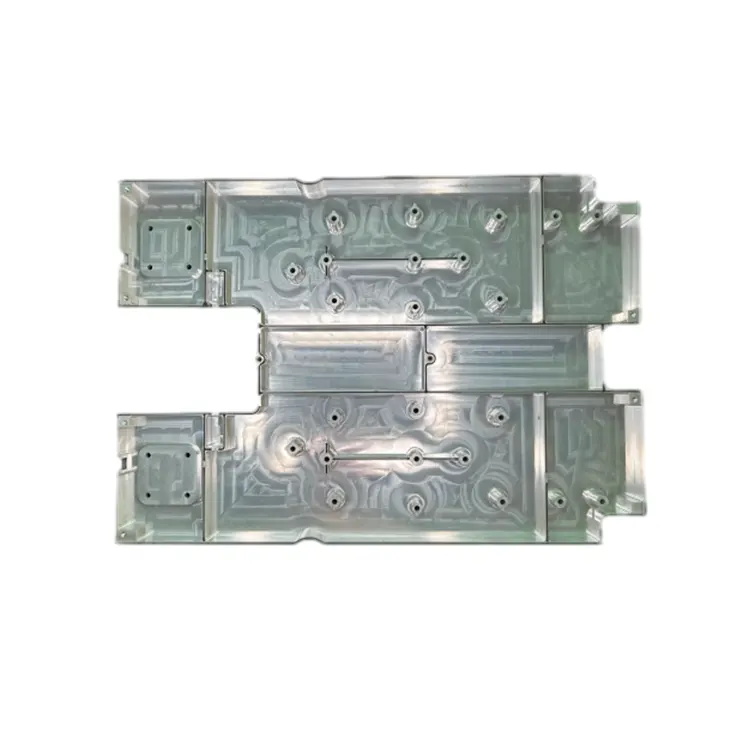

In the ever-evolving world of mechanical engineering, Cnc Mechanical Parts have become the backbone of countless industries. These parts, manufactured using the sophisticated technology of Computer Numerical Control (CNC), represent the pinnacle of precision, quality, and efficiency in mechanical component production.

CNC technology has revolutionized the manufacturing of mechanical parts. By utilizing computer programs to control machining tools, Cnc Mechanical Parts can be produced with an accuracy that was previously unattainable. This level of precision is crucial in modern engineering, where even the slightest deviation can lead to significant performance issues. Whether it's creating components for engines, machinery, or complex mechanical systems, CNC machining ensures that Cnc Mechanical Parts meet the most stringent specifications.

One of the key features of Cnc Mechanical Parts is their versatility. They can be fabricated from a wide variety of materials, including metals such as steel, aluminum, and brass, as well as plastics and composites. This allows manufacturers to select the most suitable material based on the specific requirements of the part, such as strength, durability, weight, and chemical resistance. For example, in the aerospace industry, lightweight aluminum Cnc Mechanical Parts are preferred to reduce the overall weight of aircraft while maintaining structural integrity. In the automotive sector, high-strength steel Cnc Mechanical Parts are used in critical components to ensure safety and performance.

The manufacturing process of Cnc Mechanical Parts involves several steps. First, the design of the part is created using computer-aided design (CAD) software. This digital model serves as the blueprint for the CNC machining process. Then, the appropriate material is selected and loaded into the CNC machine. The machine, guided by the CAD model and the CNC program, uses cutting tools to shape the material into the desired part. This process can include operations such as turning, milling, drilling, and grinding, depending on the complexity of the part.

The applications of Cnc Mechanical Parts are widespread and diverse. In the manufacturing industry, they are used in the production of various types of machinery, from simple hand tools to large industrial equipment. These parts ensure the smooth operation and reliability of the machinery, reducing downtime and maintenance costs. In the medical field, precision Cnc Mechanical Parts are essential for the production of medical devices and equipment. Their high accuracy and quality are crucial for ensuring the safety and effectiveness of medical treatments.

Moreover, Cnc Mechanical Parts play a vital role in the renewable energy sector. Components for wind turbines, solar panels, and hydroelectric generators are often made using CNC machining. These parts need to be durable and efficient to withstand the harsh environmental conditions and continuous operation in renewable energy systems.

The production of Cnc Mechanical Parts also offers significant benefits in terms of production flexibility and scalability. With CNC technology, manufacturers can easily modify the design of a part or produce different parts without the need for extensive retooling. This allows for quick adaptation to changing market demands and enables the production of custom-made Cnc Mechanical Parts. Additionally, CNC machining can be scaled up or down depending on the production volume, making it suitable for both small-batch and mass production.

In summary, Cnc Mechanical Parts are integral to modern mechanical engineering and manufacturing. Their precision, versatility, and the advantages offered by CNC technology make them indispensable in a wide range of industries. As technology continues to progress, Cnc Mechanical Parts will undoubtedly continue to evolve and play an even more significant role in shaping the future of various sectors.

评论

发表评论