Die Casting Parts: Precision and Durability in Manufacturing

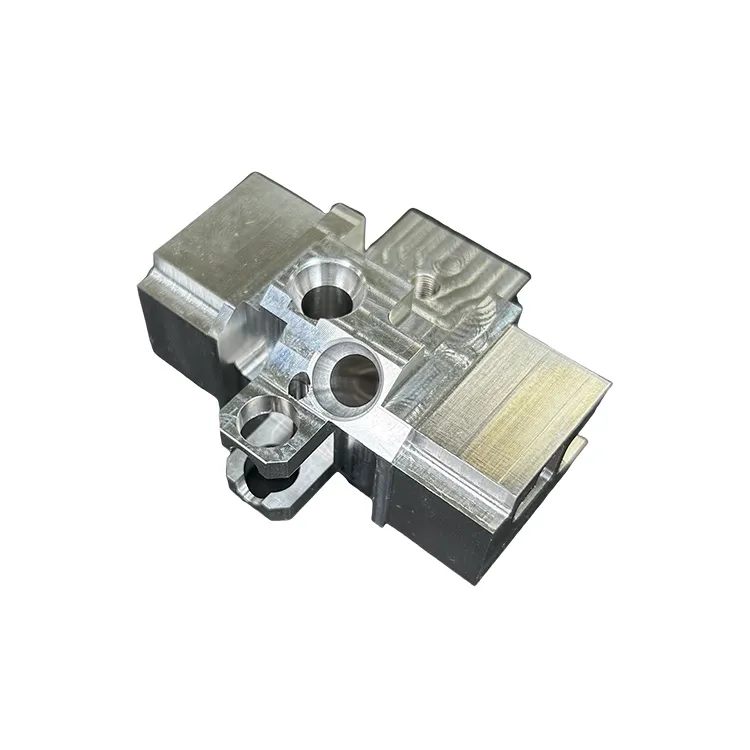

Die casting parts are an integral part of modern manufacturing, offering a wide range of benefits and applications. Die casting is a process that involves forcing molten metal under high pressure into a die or mold cavity. This method is highly efficient and can produce complex-shaped parts with high precision.

One of the main advantages of die casting parts is their excellent dimensional accuracy. The high-pressure injection of molten metal into the die ensures that the final part closely matches the dimensions of the mold. This is crucial in industries such as automotive, aerospace, and electronics, where components need to fit together precisely. For example, in the automotive industry, die-cast engine parts, such as cylinder heads and engine blocks, must have exact dimensions to ensure proper functioning of the engine.

Die casting also allows for the production of parts with a smooth surface finish. The molten metal fills the die cavity completely, resulting in a part with a uniform and smooth exterior. This reduces the need for additional finishing operations, saving both time and cost. In the electronics industry, die - cast housings for electronic devices can have a sleek and professional look right out of the die, without the need for extensive polishing or grinding.

Another key feature of die casting parts is their high strength - to - weight ratio. Depending on the type of metal used, such as aluminum or zinc, die-cast parts can be lightweight yet strong enough to withstand various mechanical stresses. In the aerospace industry, lightweight die-cast aluminum parts are used in aircraft structures to reduce overall weight while maintaining structural integrity.

The die casting process is also relatively fast, enabling high-volume production. Once the die is set up, multiple parts can be produced in a short amount of time. This makes die casting an ideal choice for mass-produced products. For example, in the production of consumer goods like household appliances, die-cast parts can be manufactured in large quantities to meet market demands.

However, die casting also has some limitations. The initial cost of the die can be high, especially for complex-shaped parts. Additionally, the process may not be suitable for all types of metals or alloys. But overall, die-casting parts continue to play a vital role in many industries due to their precision, durability, and efficiency.

评论

发表评论