Innovative Coiled Tubing Blowout Prevention Device: Everything You Need to Know

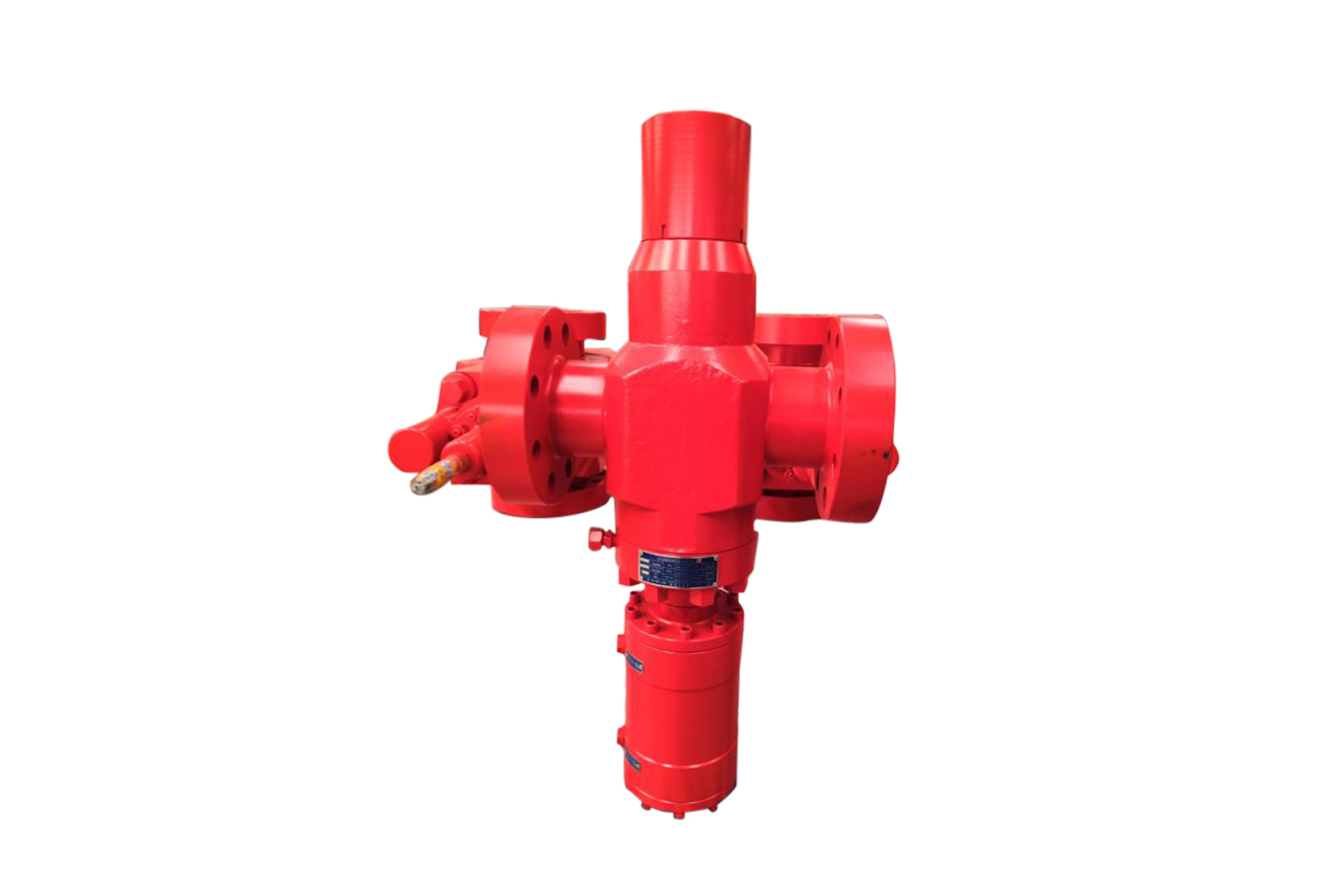

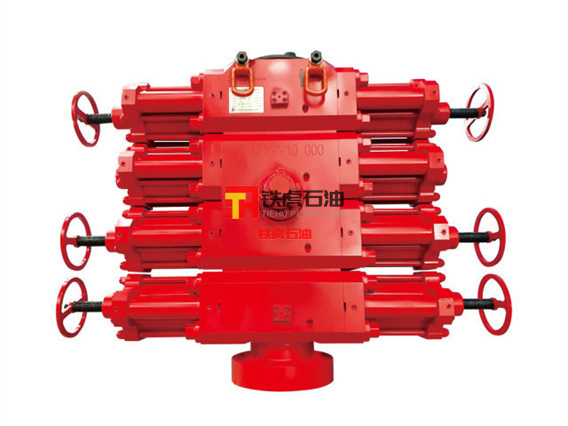

The new Coiled Tubing Blowout Prevention Device is a cutting-edge technology designed to enhance safety and efficiency in the manufacturing and processing machinery industry. This innovative device offers a range of features and benefits that make it a valuable addition to any operation. One key advantage of the Coiled Tubing Blowout Prevention Device is its ability to prevent blowouts during high-pressure operations. By effectively controlling pressure levels and flow rates, this device helps minimize the risk of accidents and ensures a safer working environment for operators. Additionally, the Coiled Tubing Blowout Prevention Device is designed for ease of use and maintenance. With user-friendly controls and durable construction, this device is built to withstand the demands of the industry and deliver reliable performance in any situation. In terms of applications, the Coiled Tubing Blowout Prevention Device can be used in a variety of scenarios, including well i...